LIT25液位指示变送器

- 低成本

- 隔离4-20mA输出(1000欧姆)

- 大型液晶显示器

- 可编程信号继电器

- 非接触式超声波传感器或可选压力传感器

- 内置2键校准器

- 防水,防尘外壳

LIT25 Level Indicating Transmitter

- Low Cost

- Isolated 4-20mA Output (1000 ohm)

- Large LCD Display

- Programmable Signal Relay

- Non-Contacting Ultrasonic Sensor or Optional Pressure Sensor

- Built-in 2-Key Calibrator

- Watertight, Dust tight Enclosure

这款全新的Greyline变送器可显示,控制和传输水平。将非接触式超声波传感器安装在水箱顶部,将紧凑,防水的电子/显示器外壳安装在附近的便利位置。操作员可以使用双键式键盘校准LIT25,而无需攀爬水箱。使用内置继电器进行电平控制或报警,使用4位大显示屏进行本地指示,并使用隔离的4-20mA输出将电平传输至PLC。

标准超声波传感器可测量高达32英尺(10米)的液位,并包括自动温度补偿。选择可选的全特氟龙传感器以实现化学兼容性,或选择一个额定至50英尺(15.6米)的传感器。所有超声波传感器都具有可选的本质安全性,可安装在危险的额定位置。LIT25还可以订购带有压力传感器的压力传感器,用于特殊应用。

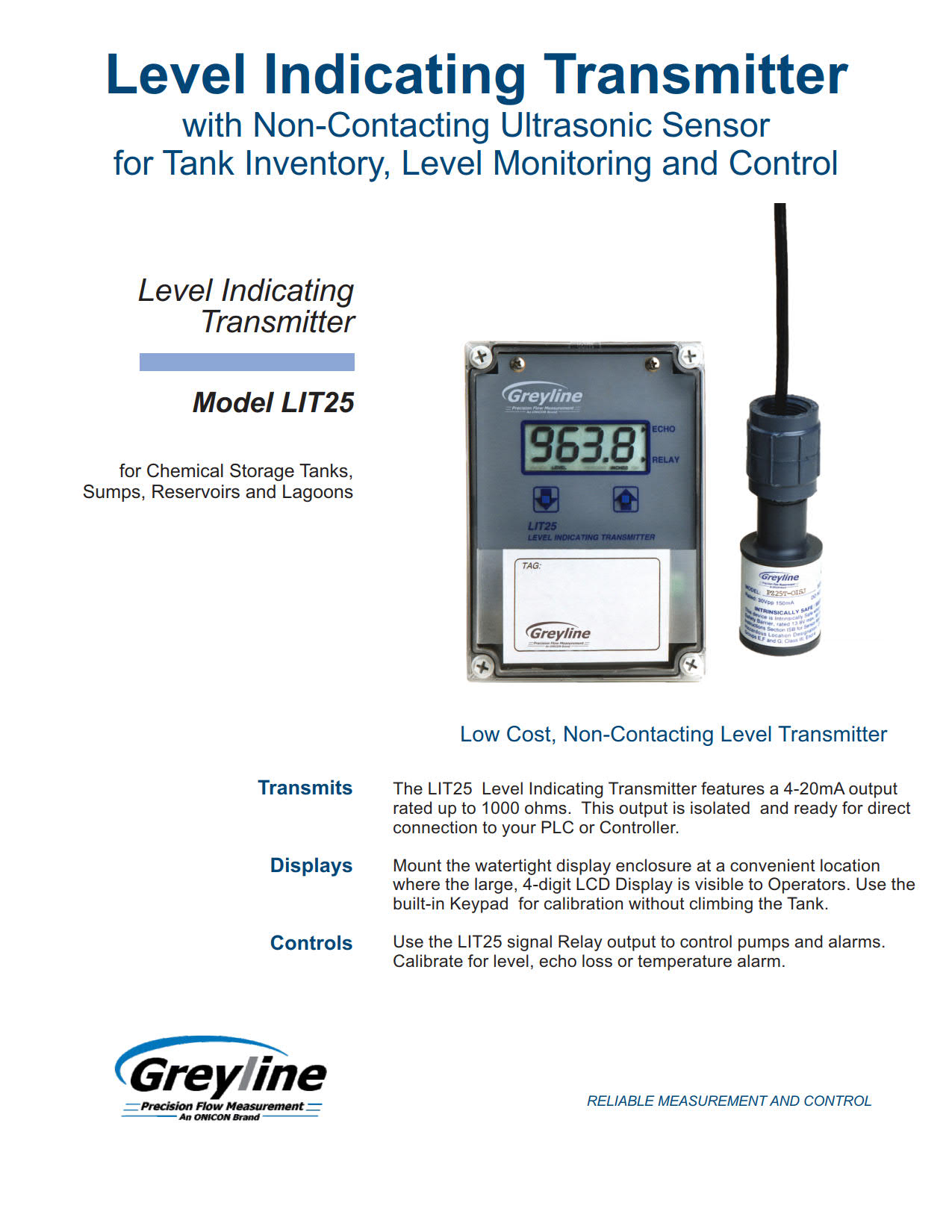

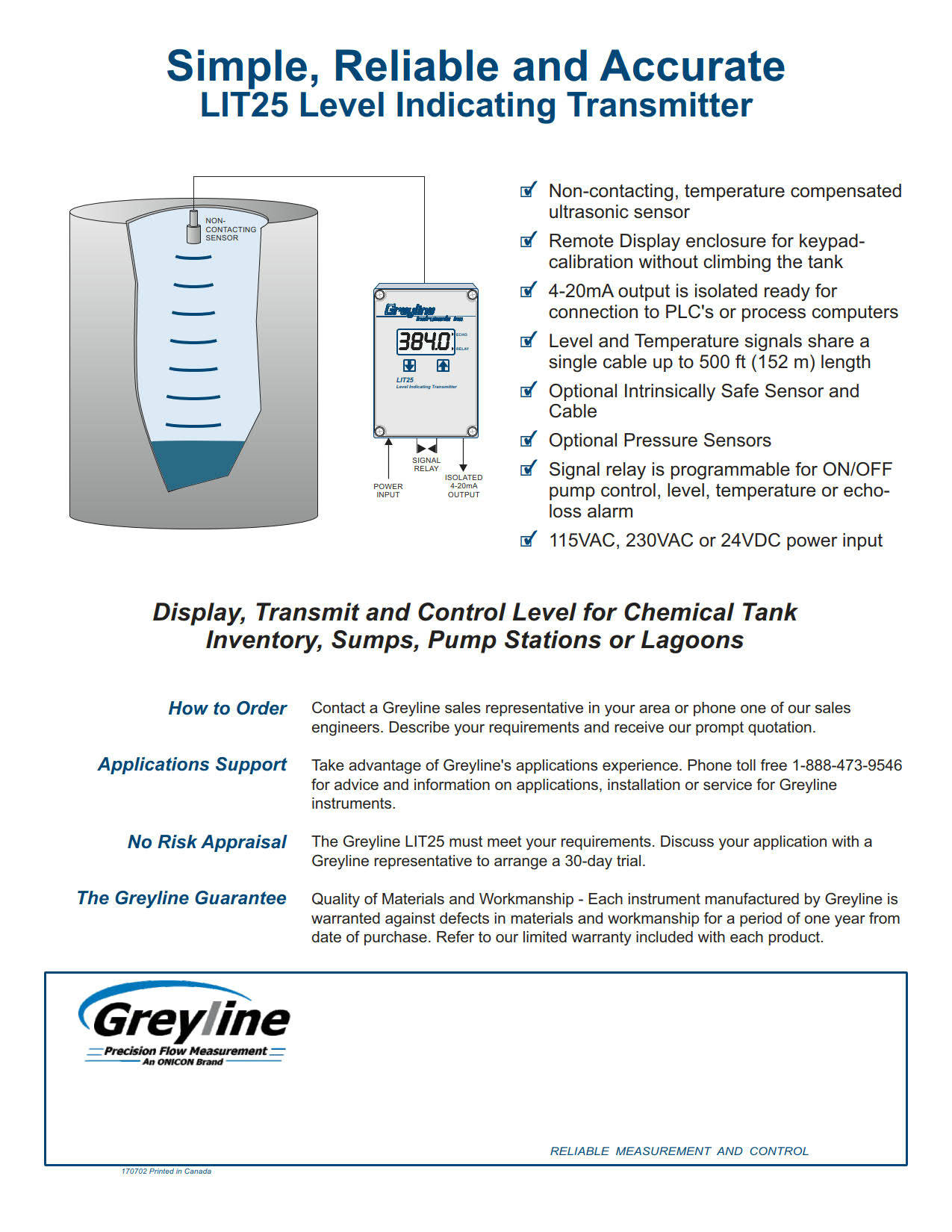

This new Greyline Transmitter displays, controls and transmits level. Mount the non-contacting ultrasonic sensor at the top of your tank and the compact, watertight electronics/display enclosure at a convenient location nearby. Operators can calibrate the LIT25 with its 2-button Keypad, without climbing the tank. Use the built-in relay for level control or alarm, the large 4-digit display for local indication, and the isolated 4-20mA output to to transmit level to a PLC.

The standard ultrasonic Sensor measures liquid levels up to 32 ft. (10 m), and includes automatic temperature compensation. Choose the optional all-Teflon sensor for chemical compatibility, or one rated to 50 ft (15.6 m) range. All ultrasonic sensors are available with optional intrinsic safety for installation in hazardous rated locations. The LIT25 can also be ordered with gauge-type pressure sensors for special applications.

液位指示变送器规格

范围:本规范涵盖由Greyline Instruments Inc.,Largo,Florida/Long Sault,Ontario制造的非接触式超声波液位指示变送器。

仪器应提供指示、传输和控制容器中的材料水平,或目标与仪器传感器的接近度。

A.性能规范

由非接触式超声波传感器、连接电缆和带有指示、传输和控制电子设备的远程外壳组成。

测量精度应为量程的±0.25%或2 mm(0.08”),以较大者为准,并应自动进行温度补偿。

传感器电缆应为RG62AU同轴电缆,总长度应符合安装要求,不得超过500 ft(152 m)。

系统应无活动部件,且不得接触被测材料。

B.非接触式传感器

传感器应采用PVC和特氟龙制成。

传感器的最小死区或空白区应为12”(305m m),最大范围为32 ft(10 m),工作频率为42 kHz,超声波束角为8_。

传感器应能承受20 psi的意外淹没。

传感器工作温度应为-40°F至150°F(-40°C至65°C)。

传感器应包括整体式温度传感器。

不接受需要单独安装和布线的温度传感器。

C.传感器连接电缆

提供连续长度为25英尺(7.6米)的RG62AU同轴电缆,并将防水封装连接至传感器头。

延伸传感器电缆应为RG62AU同轴电缆,最大500 ft(152 m)。

电缆应采用制造商推荐的NEMA4钢接线盒中的螺纹终端连接进行拼接。

水平和温度信号应在一根同轴电缆上进行。

不接受单独或多芯电缆。

传感器电缆应安装在接地金属导管中。

D.指示发送器

指示发送器应安装在壁装式防水NEMA4X(IP66)外壳内,并带有透明聚碳酸酯盖。

应包括安装硬件。

不接受需要安装在水箱顶部的组合式变送器/传感器系统。

变送器应包括一个4位大液晶显示器,其3/4”(19 mm)高的数字应在不打开外壳盖的情况下可见。

变送器应通过内置的2键校准系统进行现场校准。

不接受需要用BCD开关或外部校准器校准的系统。

校准数据应通过断电永久存储,无需备用电池。

现场校准应允许键盘选择测量范围、范围或水平操作模式,并以百分比、英寸或厘米为单位显示单位。

传送器应允许现场可编程阻尼在湍流水平条件下平稳输出,并允许可编程抑制时间忽略来自搅拌器、波和杂散回波的假信号。

变送器工作温度应为-13°F至122°F(-25°C至50°C)。

变送器应具有隔离的4-20mA输出,最大负载为1000 ohm。

输出应允许4ma和20ma的现场可编程偏移。

提供一个额定电流为1安培的信号继电器触点。

继电器应可编程用于单设定点报警、泵控制和/或回波损耗报警。

应在交流电源输入、传感器和4-20 mA输出端对变送器电子设备进行浪涌保护。

变送器电源输入应为120VAC 50/60Hz,功耗小于等于5瓦。

E.按要求插入规范的附加功能:

变送器电源输入应为200-250VAC 50/60Hz,最大功耗不超过5瓦特。

变送器电源输入应为24伏直流电,最大功耗不超过5瓦。

具有PZ34型全聚氯乙烯超声波传感器,最大范围为32英尺(10米),设计用于泵站应用。

采用PZ32TE型全特氟隆传感器,最大范围为32英尺(10米),工作温度为-40°F至170°F(-40°C至76°C)。

有一个pvc和特氟隆传感器型号pz56,适用于高达50英尺(15.6米)的液体测量范围。

具有一个聚四氟乙烯面法兰安装传感器型号PZ34TXF,额定测量范围为32英尺(10米)。

指定法兰尺寸为4“或6”。

包括制造商推荐的延长电缆长度的传感器电缆接线盒。

传感器、连接电缆和接线盒的本质安全等级应为I、II、III级,I、II类,C、D、E、F、G组。

F

.制造商

仪器应为Greyline Instruments Inc.制造的Lit25型超声波液位传感器,并保证一年内不会出现材料和工艺缺陷。

规格如有更改,恕不另行通知。如果您在申请中需要更多信息或建议,请联系Greyline。我们可以提供报价,并向贵公司所在地区的Greyline销售代表咨询。

LEVEL INDICATING TRANSMITTER SPECIFICATIONS

SCOPE: This specification covers a non-contacting, ultrasonic Level Indicating Transmitter as manufactured by Greyline Instruments Inc., Largo, Florida / Long Sault, Ontario. The instrument shall provide for indicating, transmitting and control of the material level in a vessel, or proximity of a target to the Instrument Sensor.

A. PERFORMANCE SPECIFICATIONS

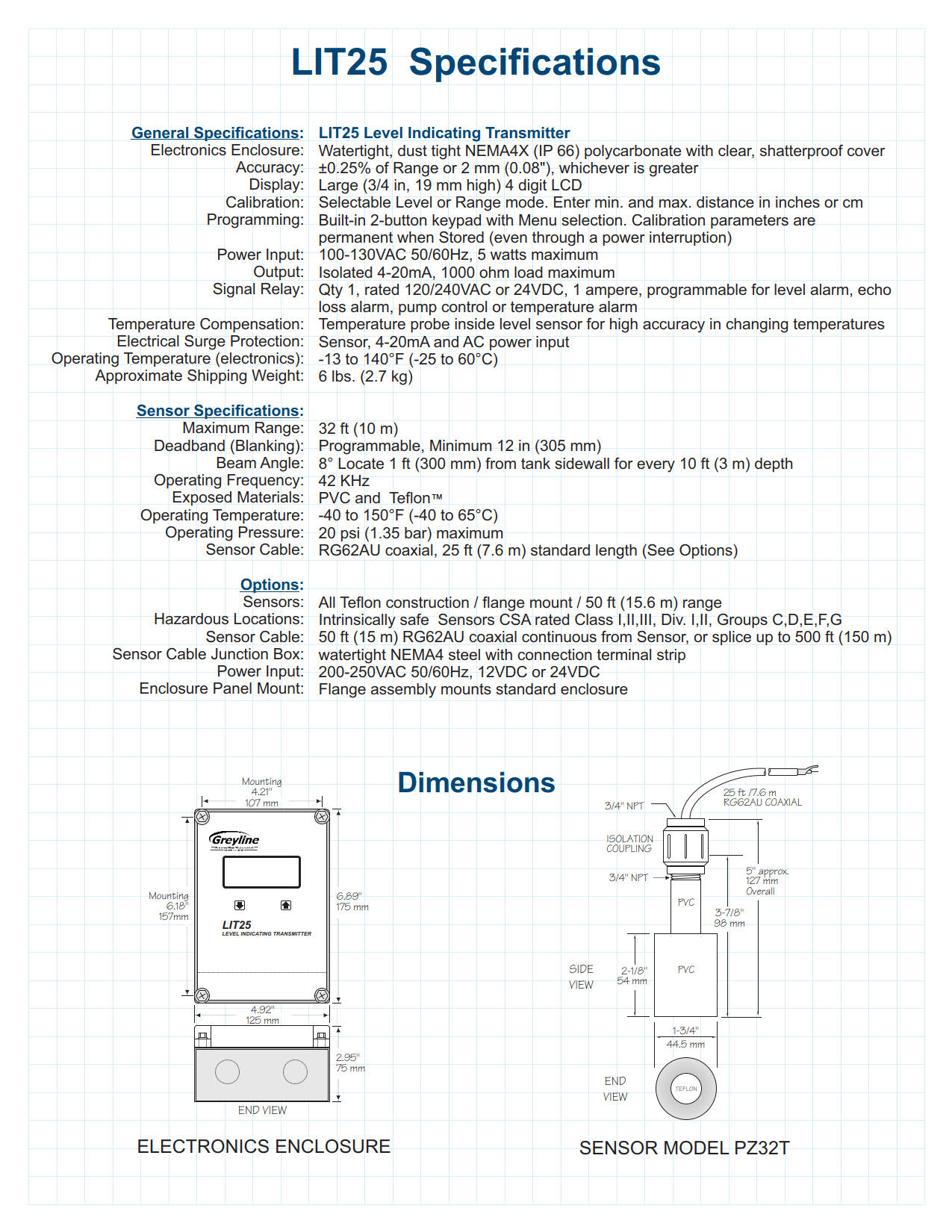

To consist of a non-contacting ultrasonic sensor, connecting cable, and a remote enclosure with indicating, transmitting and controlling electronics.

Measurement accuracy shall be ±0.25% of Range or 2 mm (0.08″), whichever is greater, and shall be automatically temperature compensated.

Sensor cable shall be RG62AU coaxial with total length as required for installation, not to exceed 500 ft (152 m).

System shall have no moving parts and shall not contact the material being measured.

B. NON-CONTACTING SENSOR

Sensor shall be constructed of PVC and Teflon.

The sensor shall have a minimum deadband or blanking of 12″ (305mm) and a maximum range of 32 ft (10 m), and have an operating frequency of 42 kHz with an ultrasonic beam angle of 8?.

Sensor shall withstand accidental submersion to 20 psi.

Sensor operating temperature shall be from -40°F to 150°F (-40°C to 65°C).

Sensor shall include integral temperature sensor. Temperature sensors requiring separate mounting and wire runs shall not be accepted.

C. SENSOR CONNECTING CABLE

Provide RG62AU coaxial cable 25 ft (7.6 m) continuous length, with waterproof, potted bond to the Sensor head.

Extended sensor cable shall be RG62AU coaxial to a maximum of 500 ft (152 m). Cable shall be spliced with screw terminal connections in manufacturer’s recommended steel NEMA4 Junction Box.

Level and temperature signals shall be conducted on one single coaxial cable. Separate or multiple-conductor cables shall not be accepted.

Sensor cable shall be installed in grounded metal conduit.

D. INDICATING TRANSMITTER

The Indicating Transmitter shall be housed in a wall-mount, watertight NEMA4X (IP66) enclosure with clear, polycarbonate cover. Mounting hardware shall be included. Combined Transmitter/Sensor systems requiring mounting at the top of a tank shall not be accepted.

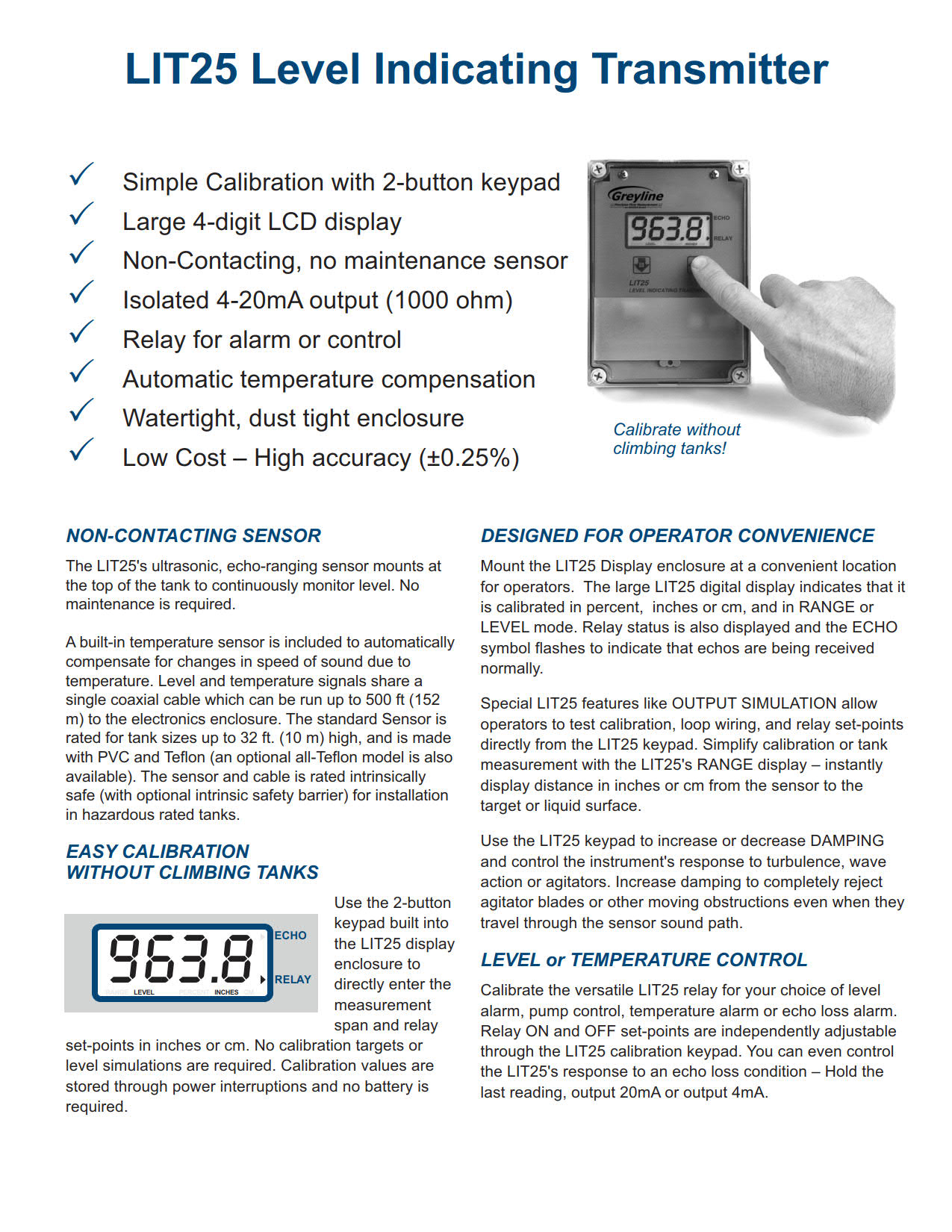

Transmitter shall include a large 4-digit LCD display with 3/4″ (19 mm) high digits that shall be visible without opening the enclosure cover.

The transmitter shall provide for field-calibration via built-in 2-key calibration system. Systems requiring calibration by BCD switches or external calibrators shall not be accepted.

Calibration data shall be permanently stored through power interruptions without requirement of a back-up battery.

Field calibration shall allow keypad selection of measurement span, Range or Level operating modes, and display units in Percent, Inches or Centimeters.

Transmitter shall permit field programmable damping to smooth output in turbulent level conditions, and programmable rejection time to disregard false signals from agitators, waves and spurious echoes.

Transmitter operating temperature shall be from -13°F to 122°F (-25°C to 50°C).

Transmitter shall have an isolated 4-20mA output into a 1000 ohm maximum load. Output shall allow field programmable offsets of 4mA and 20mA.

Provide one signal relay contact rated 1 amp. Relay shall be programmable for single set point alarm, pump control, and/or echo loss alarm.

Transmitter electronics shall be surge protected on AC power input, sensor and 4-20 mA output.

Transmitter power input shall be 120VAC 50/60Hz with power consumption of 5 Watts or less.

E. ADDITIONAL FEATURES FOR INSERTION IN SPECIFICATION AS REQUIRED:

Transmitter power input shall be 200-250VAC 50/60Hz with maximum power consumption of 5 watts or less.

Transmitter power input shall be 24VDC with maximum power consumption of 5 watts or less.

Have an all-PVC ultrasonic sensor model PZ34 rated for 32 ft (10 m) maximum range and designed for pump station applications.

Have an all-Teflon sensor model PZ32TE rated for 32 ft (10 m) maximum range and operation from -40°F to 170°F (-40°C to 76°C).

Have a PVC and Teflon sensor model PZ56 rated for measurement range on liquids up to 50 ft (15.6 m).

Have a Teflon-faced flange mount sensor model PZ34TxF rated for 32 ft (10 m) measurement range. Specify flange size of 4” or 6”.

Include manufacturer’s recommended sensor cable Junction Box for extended cable lengths.

Sensor, connecting cable and junction boxes shall be rated intrinsically safe to Class I,II,III, Div. I,II, Groups C,D,E,F,G.

F. MANUFACTURER

The instrument shall be a Model LIT25 Ultrasonic Level Transmitter as manufactured by Greyline Instruments Inc., and warranted against defects in materials and workmanship for one year.

Specifications are subject to change without notice. Please contact Greyline if you need more information or for advice in your application. We can provide quotations and refer you to the Greyline sales representative in your area.

流量计运作原理

仪器电子设备测量从发送声音到回声返回所需的时间。根据空气中的声速,可以高精度计算出液体表面与传感器的准确距离(0.25%范围)。

由于声速受空气温度的影响,灰线超声波液位传感器包括一个内置的温度传感器。水平/距离测量在传感器的整个工作温度范围内自动进行温度补偿。

传感器的位置应使其能清楚地“看到”液体表面,远离梯子、管道或其他障碍物。Greyline建议每10英尺深度距离侧壁1英尺(每3米深度300毫米)。来自搅拌器的假回波(在传感器下扫过)、湍流和波可以被仪器过滤和忽略。

Greyline模型的范围从简单的4-20mA液位指示发送器,到复杂的监控、控制和数据记录模型。返回greyline产品了解级别模型详细信息和规格。有关包括超声波在内的各种液位仪表技术的信息,请参阅废水液位测量技术。

测量管外脏污或充气液体的流量

多普勒效应由奥地利物理学家克里斯蒂安·多普勒于1842年提出。我们每天都能听到多普勒的例子:火车经过时的汽笛声改变音调,或者赛车驶过我们的位置时的排气噪音。

多普勒技术只适用于含有固体或气泡的液体来反射其信号。这些是“困难”的液体,可能会损坏常规流量计:泥浆、污泥、废水、磨料、粘性和腐蚀性化学品。由于传感器安装在管道外部,因此没有压降,也没有流动障碍物。

为了获得很好性能,多普勒传感器应安装在远离湍流产生装置(如弯管和三通)的地方,远离速度增加装置(如控制阀和泵)。典型精度为满刻度的±2%。多普勒仪器包括一个夹式超声波传感器、连接电缆和一个电子外壳,可以安装在附近方便的位置(500英尺/152米范围内)。传感器可以本质安全地额定安装在危险的额定位置。

需要非常精确的定时电路,但当传感器可以安装在流量均匀分布的管段上时,1%的精度非常典型。

由于超声波信号必须穿过管道到达接收传感器,因此流体中不得含有大量气泡或固体(小于2%)。否则高频声音会减弱,太弱,无法穿过管道。应用包括饮用水、冷却水、水/乙二醇溶液、液压油、燃油和化学品。

渡越时间传感器通常工作在1-2兆赫的频率。高频设计通常用于较小的管道,低频设计用于直径达数米的大型管道。

水槽和堰是专门设计的渠道形状,以表征水流。常见的类型有矩形堰、V型槽堰、Parshall水槽和Palmer Bowlus水槽。水槽或堰型的选择取决于应用:流速、渠道形状和水的固体含量。请联系Greyline Instruments以获取有关为您的应用选择合适水槽或堰的建议。

灰线明渠流量计可以通过菜单选择校准到水槽或堰。明渠流量计电子设备使用内部公式计算流量(流量=k h n,其中“k”和“n”为常数,“h”为仪器测量的压头)。通过直接输入“k”和“n”常数,可以对不常见或自定义水槽进行校准。Greyline还提供了一个PC软件程序“find k&n”,用于根据水槽或堰流图开发校准常数。

Greyline明渠流量计包括非接触式超声波传感器、连接电缆和电子外壳,可安装在附近方便的位置(500 ft/152 m内)。传感器可以本质安全地额定安装在危险的额定位置。仪器显示、汇总、传输和控制,有些型号包括数据记录/流量报告系统。

在没有水槽或堰的情况下测量明渠流量。面积速度流量计连续测量水位和流速,以计算明渠或管道中的流量。

超声波传感器安装在管道或通道的底部。为了测量水位,传感器发送超声波脉冲,这些脉冲通过水传播并从液体表面反射出来。仪器精确测量回声返回传感器所需的时间。根据水中声速,测量声级精度为±0.25%。

用连续注入水中的超声多普勒信号测量流速。这种高频声音(640kHz)从悬浮在液体中的颗粒或气泡反射回传感器。如果流体在运动,回声以与流速成比例的变化频率返回。利用该技术,仪器测量流速的精度为±2%。

greyline面积流速流量计工作在部分满管和溢流管、矩形、梯形和蛋形通道中。

可选-单独的液位和速度传感器

一个单独的向下看超声波传感器可用于高充气或湍流应用。它通过将超声波脉冲通过空气传输到液体表面来测量液位,精度为±0.25%。在水位传感器的基础上,采用水下多普勒速度传感器对水位进行测量。

HOW IT WORKS

The instrument electronics measure the time it takes from transmitted sound to return of the echo. With reference to the speed of sound in air, the exact distance of the liquid surface from the sensor can be calculated with high accuracy (±0.25% of maximum range).

Since the speed of sound is affected by air temperature, Greyline ultrasonic level sensors include a built-in temperature sensor. Level/distance measurements are automatically temperature compensated throughout the operating temperature range of the sensor.

The sensor should be positioned so that it has a clear “view” of the liquid surface and away from ladders, pipes or other obstructions. Greyline recommends 1 ft. from the sidewall for every 10 ft. depth (300 mm for every 3 m depth). False echoes from agitators (sweeping under the sensor), turbulence and waves can be filtered and disregarded by the instrument.

Greyline models range from simple 4-20mA level indicating transmitters, to sophisticated monitoring, controlling and data logging models. Return to Greyline Products for Level model details and specifications. For information on a wide range of level instrument technologies including ultrasonics, read Wastewater Level Measurement Techniques.

Doppler flow meters measure flow from outside a pipe with a clamp-on sensor. Greyline Doppler meters continuously transmit high frequency sound (640 kHz) that travels through the pipe wall and into the flowing liquid. Sound is reflected back to the sensor from solids or bubbles in the fluid. If the fluid is in motion, the echoes return at an altered frequency proportionate to flow velocity. Doppler flow meters continuously measure this frequency shift to calculate flow.

Measure Flow of dirty or aerated Liquids from Outside a Pipe

The Doppler effect was first documented in 1842 by Christian Doppler, an Austrian physicist. We hear everyday examples of Doppler: the sound of a train whistle changing pitch as it passes by, or the exhaust noise from a race car as it speeds past our location.

The Doppler technique only works on liquids which contain solids or gas bubbles to reflect its signal. These are “difficult” liquids that may damage regular flow meters: slurries, sludge, wastewater, abrasives, viscous and corrosive chemicals. Because the sensor mounts on the outside of the pipe, there is no pressure drop and no obstruction to flow.

For best performance Doppler sensors should be mounted away from turbulence creating devices like pipe elbows and tees, and away from velocity increasing devices like controlling valves and pumps. Typical accuracy is ±2% of full scale. Doppler instruments include a clamp-on ultrasonic sensor, connecting cable and an electronics enclosure which can be mounted at a convenient location nearby (within 500 ft / 152 m). Sensors can be rated intrinsically safe for mounting in hazardous-rated locations.

Very accurate timing circuits are required but 1% accuracy is quite typical when the transducers can be mounted on a pipe section with evenly distributed flow.

Because the ultrasonic signal must cross the pipe to a receiving transducer, the fluid must not contain a significant concentration of bubbles or solids (less than 2%). Otherwise the high frequency sound will be attenuated and too weak to traverse the pipe. Applications include potable water, cooling water, water/glycol solutions, hydraulic oil, fuel oils and chemicals.

Transit Time transducers typically operate in the 1-2 MHz frequencies. Higher frequency designs are normally used in smaller pipes and lower frequencies for large pipes up to several meters in diameter.

Flumes and weirs are specially designed channel shapes that characterize the flow of water. Common types are Rectangular Weirs, V-Notch Weirs, Parshall flumes and Palmer Bowlus flumes. The choice of flume or weir type depends on the application: flow rate, channel shape and solids content of the water. Contact Greyline Instruments for advice on selection of a suitable flume or weir for your application.

Greyline open channel flow meters can be calibrated to any flume or weir by menu selection. The open channel flow meter electronics use an internal formula to calculate flow rate (Flow = K Hn, where ‘K’ and ‘n’ are constants and ‘H’ is Head as measured by the instrument). Calibration to uncommon or custom flumes can be done by direct entry of ‘K’ and ‘n’ constants. Greyline also offers a PC software program “Find K&n” to develop calibration constants from a flume or weir flow chart.

Greyline open channel flow meters include a non-contacting ultrasonic sensor, connecting cable and an electronics enclosure which can be mounted at a convenient location nearby (within 500 ft / 152 m). Sensors can be rated intrinsically safe for mounting in hazardous-rated locations. The instruments display, totalize, transmit and control, and some models include data logging/flow reporting systems.

Measure open channel flow without a flume or weir An Area-Velocity Flow Meter continuously measures both Level and Velocity to calculate flow volume in an open channel or pipe.

The ultrasonic sensor is installed at the bottom of a pipe or channel. To measure water level the sensor transmits ultrasonic pulses that travel through the water and reflect off the liquid surface. The instrument precisely measures the time it takes for echoes to return to the sensor. Based on the speed of sound in water, the level is measured with accuracy of ±0.25%.

Flow velocity is measured with an ultrasonic Doppler signal continuously injected into the water. This high frequency sound (640 KHz) is reflected back to the sensor from particles or bubbles suspended in the liquid. If the fluid is in motion, the echoes return at an altered frequency proportionate to flow velocity. With this technique the instrument measures flow velocity with accuracy of ±2%.

Greyline Area-Velocity Flow Meters work in partially full and surcharged pipes, rectangular, trapezoid and egg-shaped channels.

Optional – Separate Level and Velocity Sensors

A separate down-looking ultrasonic sensor can be used for highly aerated or turbulent flow applications. It measures level by transmitting ultrasonic pulses through the air to the liquid surface with accuracy of ±0.25%. Along with the level sensor, a submerged Doppler velocity sensor is used to measure the water velocity.