数字弯曲台BGD-5?eco??Ref.No.?42380

BGD-5?eco为母线弯曲设定了新标准,具有很好的精度和速度,价格经济实惠。配备必备 – 数字角度编码器 – BGD-5?eco提供简单性和控制,全自动回弹补偿和0.25度弯曲精度。

因此,它将消除对试验弯曲的需求,并显着降低故障弯曲母线的成本。重要的是,数字行程编码器可以在短的循环时间内很大限度地减少空转。步进式或边缘弯曲机等附加配件也可通过数字行程编码器轻松精确地控制。新型集成液压动力单元将弯曲速度提升到新的水平–11.5秒 – 完成90度弯曲,包括全自动回弹补偿。

好处

- 以经济的价格提供弯曲功能

- 数字角度编码器,精度为+/- 0.25度

- 全自动回弹补偿

- 没有试验弯曲;?没有设置时间

- 数字行程编码器,可缩短循环时间

- 提供内置高性能三相电源组

- 用于特殊弯曲应用的可选步进和弯边工具

- 紧L-,U-和Z-弯曲成为可能

- 便携式机器在轮子上易于使用

Digital Bending Bench BGD-5eco?Ref.No. 42380

The BGD-5eco sets a new standard for busbar bending with outstanding precision and speed at economical prices. No other bending machine will match it‘s range of features and performance at low entry price levels. Equipped with the essential – Digital Angle Encoder – the BGD-5eco offers unsurpassed simplicity and control with full automatic spring back compensation and bending accuracy to 0.25 degrees.

Consequently it will vanquish any need for trial bends and significantly reduce cost on faulty bend busbars. On top of this, the digital stroke encoder minimizes idle movement for the absolute shortest cycle times. Additional accessories like step or edge benders are also easy and preciseley controlled by the digital stroke encoder. The new integrated hydraulic power pack takes bending speeds to new levels – 11.5 seconds – for a finished 90 degree bend including full automatic spring back compensation.

Advantages

- unsurpassed bending features at economic price

- digital Angle Encoder with precision to +/-0.25 degrees

- full automatic spring back compensation

- no trial bends; No set up times

- digital Stroke Encoder for minimum cycle times

- supplied with built in high performance 3-phase power pack

- optional step and edge bending tools for special bending applications

- tight L-, U- and Z-bends possible

- portable machine on wheels for ease of use

| 高度 | 1,130毫米 |

|---|---|

| 深度 | 950毫米 |

| 宽度 | 830毫米 |

| 重量 | 170公斤 |

| 运营压力 | 200巴 |

| 力 | 180 KN |

| 最大弯曲能力 | 160 x 13毫米(6“x1 / 2”) |

| 弯曲半径适配器 | 7.5;?10;?15毫米 |

| 额定功率 | 0.75千瓦 |

|---|---|

| 电压 | 400 V 3~ / 50 Hz |

| 油流量 | 3.6升/分钟 |

| 周期* | 11.5秒 |

| 循环时间**(重复操作) | 9.4秒 |

| 最小L弯曲 | 25毫米 |

| 最小U形弯曲 | 60毫米 |

| 最小Z弯曲 | 70毫米 |

* 90°弯曲,120 x 10 mm母线尺寸,返回行程包括。全自动回弹补偿

** 90°弯曲,120 x 10 mm母线尺寸重复操作

| Height | 1,130 mm |

|---|---|

| Depth | 950 mm |

| Width | 830 mm |

| Weight | 170 kg |

| Operating Pressure | 200 bar |

| Force | 180 KN |

| Bending capacity max. | 160 x 13 mm (6″x1 /2”) |

| Bending radius adaptors | 7.5; 10; 15 mm |

| Power rating | 0.75 kW |

|---|---|

| Voltage | 400 V 3~/50 Hz |

| Oil flow | 3.6 l/min |

| Cycle time* | 11.5 sec. |

| Cycle time**?(repeat operation) | 9.4 sec. |

| Minimum L-Bend | 25 mm |

| Minimum U-Bend | 60 mm |

| Minimum Z-Bend | 70 mm |

* 90° bend, 120 x 10 mm busbar size, return stroke incl. full automatic spring back compensation

** 90° bend, 120 x 10 mm busbar size repeated operation

偏移弯曲工具Ref.No.?31671(小),Ref.No。31188(大)

两种不同的偏置弯曲工具可为您的开关设备提供非常短且100%的平行偏移弯曲。一个用于铜母线,最大尺寸为80 x 8 mm(小),第二个用于120 x 10 mm母线(大)。

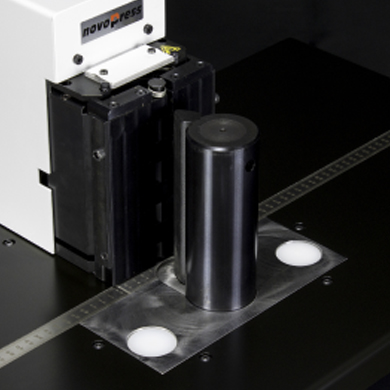

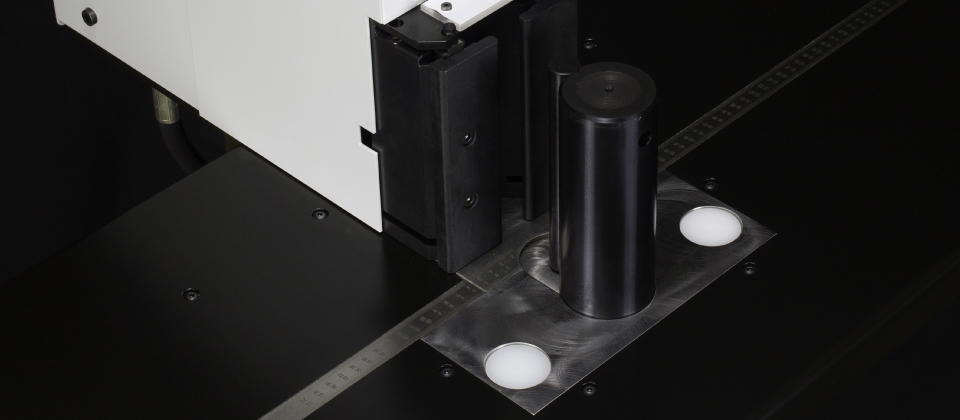

平弯工具Ref.No.?31221

使用我们独特的平弯工具铜母线,最大50 x 10 mm可以90°平弯。特别是在开关柜中的接地母线上,可以节省许多90°螺栓连接。

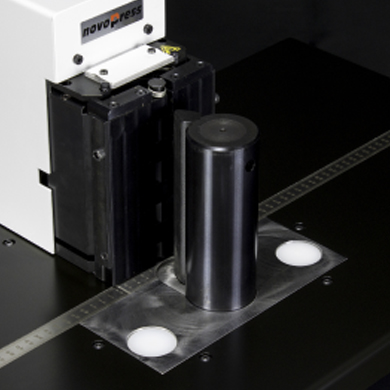

Supplementary-Bender-BGD Ref.No.31850

L型弯曲工具允许极短的L形弯曲,腿长仅25 mm。因此,即使在具有非常紧密的安装空间的开关设备上,也可以容易地进行断路器连接。对于现代开关设备或面板制造商来说不可或缺。

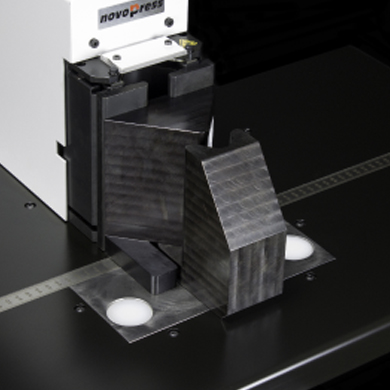

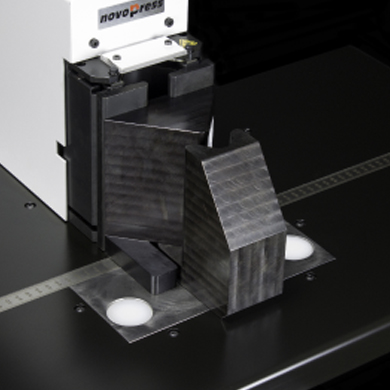

Z-Bending-Tool Ref.No.?45470(小),Ref.No。45810(大)

通过使用弯曲延伸“Z”,可以产生特殊的阶梯弯曲。为此,我们提供两种不同的选择。使用较小的台阶弯曲工具可以在铜中弯曲90°“Z”,最大尺寸为120 x 6 mm,内部尺寸(内部到内部)为27 mm。较大的阶梯弯曲工具允许在铜材料中弯曲90°“Z”,最大尺寸为100 x 10 mm,内部尺寸(内部到内部)为30 mm。

支持BGD-5?eco?Ref.No.?43255

软件包“NovoBend”

使用我们的附加软件包“NovoBend”,可以在任何外部PC上编辑弯曲程序。

Offset-Bending-Tools Ref.No. 31671 (small), Ref.No. 31188 (large)

Two different Offset-Bending-Tools enable very short and 100% parallel offset bendings for your switchgear. One for copper busbar up to 80 x 8 mm (small) and the second for 120 x 10 mm busbar (large).

Flat-Bending-Tool Ref.No. 31221

With our unique Flat-Bending-Tool copper busbars up to 50 x 10 mm can be 90° flat bended. Especially on grounding busbars in the switchgear, many 90° bolt connections can be saved.

Supplementary-Bender-BGD Ref.No.31850

The L-Bending-Tool allows extremely short L-bends with only 25 mm leg length. Thus, even on switchgear with very tight installation space, circuit breaker connections can be made with ease. Indispensable for modern switchgear or panel manufacturers.

Z-Bending-Tool Ref.No. 45470 (small), Ref.No. 45810 (large)

By using the bending extension “Z” special step bendings can be produced. For this purpose we offer two different options. With the smaller step bending tool can be bent a 90° “Z” in copper with a maximum of 120 x 6 mm and an internal dimension (inside to inside) of 27 mm. The larger step bending tool allows bends of a 90° “Z” in copper material with a maximum of 100 x 10 mm and an internal dimension (inside to inside) of 30 mm.

Support for BGD-5eco Ref.No. 43255

Software package “NovoBend”

With our additional software package “NovoBend” bending programs can be edited on any external PC.